-40%

SOUTH BEND 9/10K METAL LATHE METRIC TRANSPOSING CHANGE GEAR 80/63

$ 26.37

- Description

- Size Guide

Description

Why choose the 80/63T combination, It makes the best sense!Read on further!

SOUTH BEND 9 and 10K METAL LATHE METRIC TRANSPOSING Gear Set

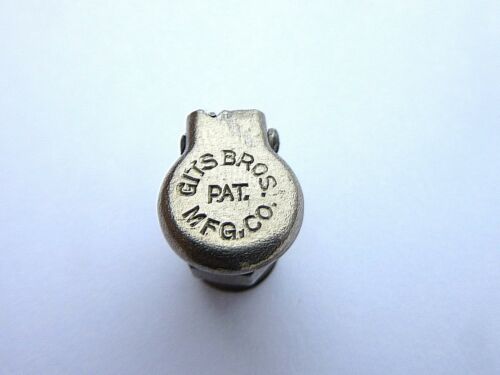

Powdered Metal Bronze (SAE 841) oil impregnated bushing.

There IS also an oil hole if you desire to oil directly. (Makes me feel better ;>) )

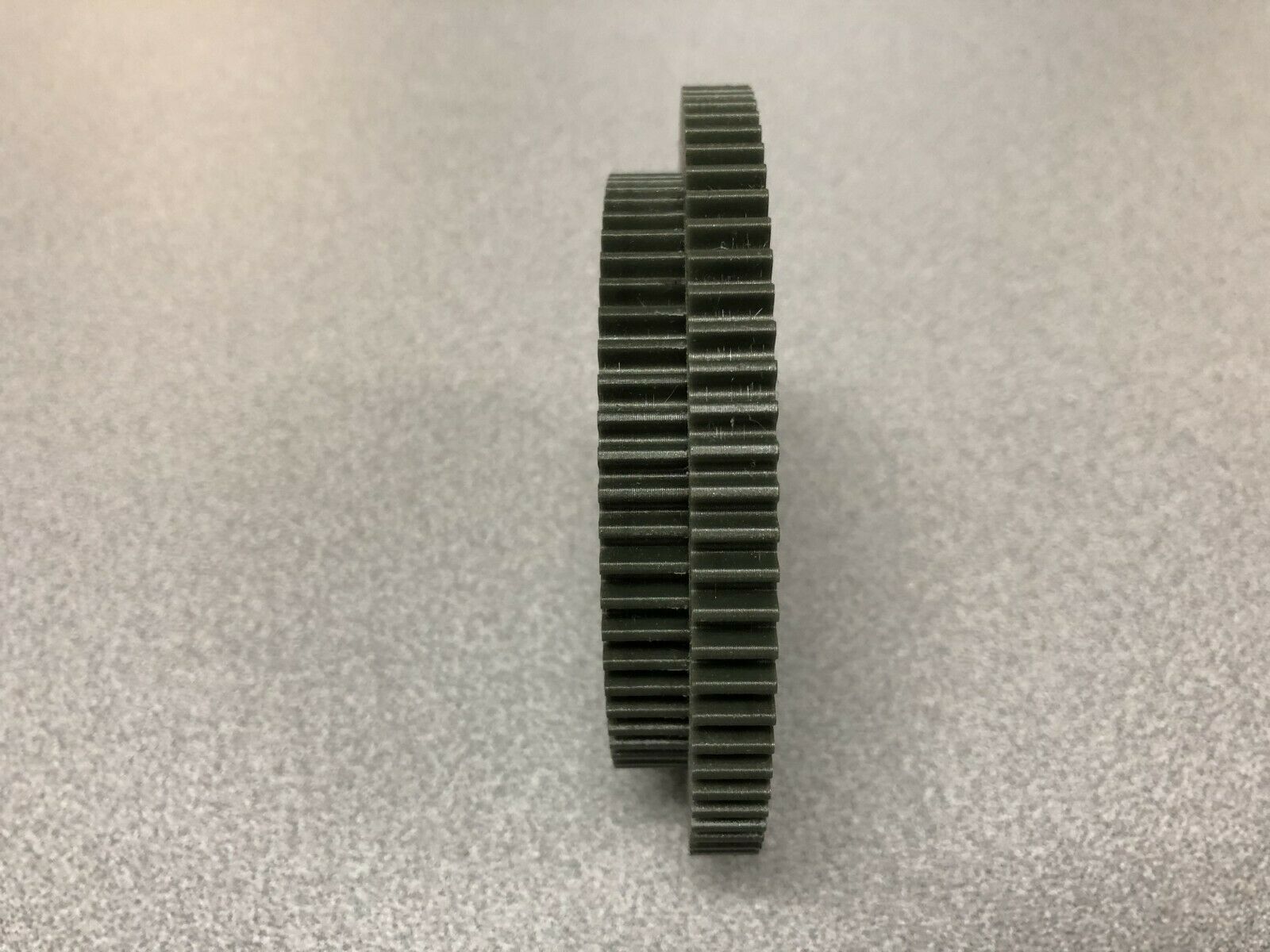

3d printed Metric Transposing Gear 80/63 toothed. (Your existing gear it replaces should be 80 also but does not have to be.)

Commonly used to transpose the feed rates on metal lathes to allow cutting of metric sized threads.

While not perfect this IS the most accurate combination, besides the factory stock 127/100 tooth gear.

This 80/63 gear ratio is 1/1.27.

the resultant error is 0.0015” per foot of threading!

This gear is nearly 2 times as accurate (1/2 as much error) as the 47/37 commonly sold and used.

Gear Dimensions:

80t Gear Width

: 0.375”

63T Gear Width

: 0.450”

(this provides enough offset to “clear” each other an retain FULL 0.375 engagement.

Bore Diameter:

0.625” (retain use of any existing bushings).

RUN QUIET!!

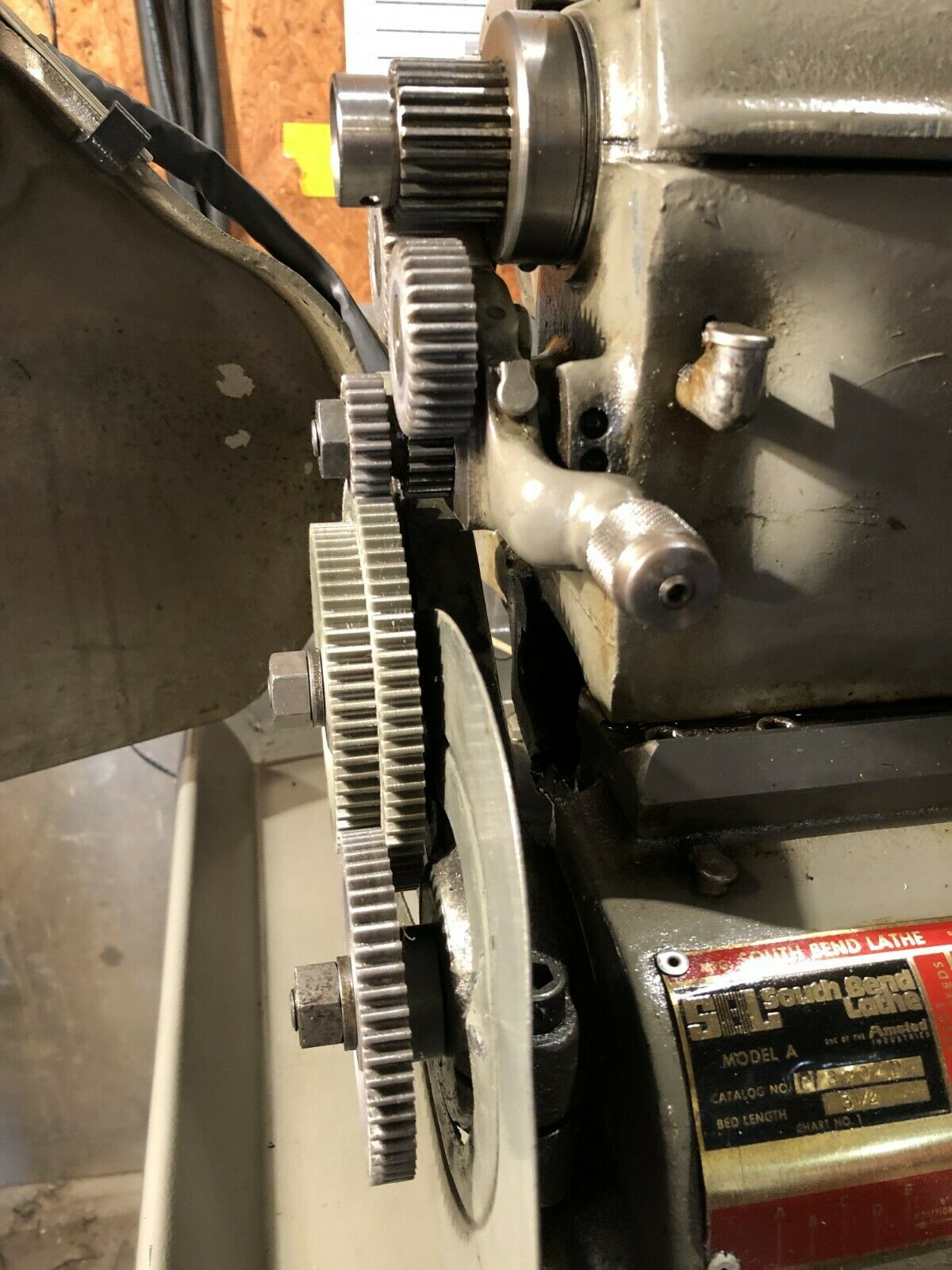

You can replace your current 80T gear with this Transposing gear with NO CHANGES.

You will be happy with the reduction in gear noise.

Run it all the time just for that!!!!

I have run these gears against STEEL gears and other PLASTIC gears for MANY hours of use.

I have accidentally had SWARF sucked into the plastic gears. (Had to dig it out!)

I HAVE EPERIENCED NO MEASURABLE WEAR AND NO FAILURE TO DATE!

These gears seem to be REALLY TOUGH!

I have been very impressed and think you will be to!

On the 9 and 10 K the 80/63 tooth transposing gear can be LEFT INSTALLED ALL THE TIME to enjoy a QUIET gear train!

No other transposing gear (47/37 or 127/100) allow this!

Plus you can CLOSE THE GEAR COVER for added

quietness

and SAFETY!

Thanks for looking!!!

Why I choose the 80/63T combination, It made the best sense!

See below for more information.

Following is some GREAT gear threading information.

Metric Threading on the Lathe

Metric threading using a lathe with an inch lead screw isn't difficult, but instructions that cover the finer points are few and far between. It's a metric world and I now cut more metric threads than anything else. Chances are, if you're not cutting metric threads now, you will be sooner or later. My guess is sooner. With just a few extra gears you can cut any standard metric pitch on your small Logan, Southbend or other quality lathe. The following explanation may seem a bit tedious and repetitive, but a solid understanding of the basics will help you solve any problems that might arise, for any lathe, gear train or pitch.

Metric Transposing Gears & How They Work

The most common lead screw is 8 TPI, a pitch of 0.125". That's 3.175 mm, not a terribly convenient number from which to derive the standard metric pitches. The purpose of metric transposing gears is simply to scale that pitch into a more useful value that can be divided or multiplied, using common gear ratios, to get the standard metric pitches.

The traditional pair of transposing gears have 127 and 100 teeth. The lead screw pitch, 3.175 mm, divided by the ratio of those two gears, 1.27, gives us 2.5 mm, a much easier number to further divide or multiply into standard metric pitches. The important thing to remember is that using metric transposing gears allows you to treat your inch lead screw as a metric lead screw. The rest of the gear train simply multiplies or divides that new pitch value to get to the desired pitch. If you think of the transposing gears and lead screw together it avoids having to include the specifics of the conversion in every gear calculation.

A simple example will reinforce the concept. You've installed the metric transposing gears and now think in terms of having a 2.5 mm pitch lead screw. You want to cut a 1.0 mm pitch thread so you need some gears in the path between the transposing gears and the lead screw (or spindle, depending on where the transposing gears are installed) with a ratio of 1:2.5. A 16 and 40 tooth pair would do the job (as would various others having the same ratio). If you have a lathe with a quick change gearbox, the same rules apply. You still need an overall 1:2.5 ratio, using some combination of external gears and the ratios available within the gear box. I'll cover QC gearboxes in more detail later, but for the moment we'll assume a simple change gear machine with no gear box.

Big Transposing Gears Why NOT the 127/100 gear!

The traditional 127 and 100 tooth transposing gears are big and expensive. Worse, they usually won't allow the gear cover to be closed, increasing the chance of damage from metal chips and exposing people to the hazards of an open gear train. Make no mistake, open gear trains are extremely dangerous. They will pull things in, destroying both object and gears. Think injuries and amputations.

Open un-guarded gear trains are never allowed in industry and a company would be heavily fined by OSHA for allowing such

. If you use a gear train that doesn't allow the cover to be used, fabricate a suitable guard to protect yourself and others. It may seem overly cautious, but you should also unplug the lathe whenever you're working on the gear train.

The next issue is the banjo, the frame that holds the gears and allows their relationship to be adjusted. With the large transposing gears you may need an alternate or even custom banjo. Everything is lathe dependent. Some lathes accommodate these gear trains with little trouble. Others, typically the smaller machines used by hobbyists, require some ingenuity to convert. One could, of course, obtain a metric lead screw, but it's far easier to swap gears than lead screws.

The 127 and 100 tooth gears are the smallest gears that offer an exact metric conversion. If you were making lead screws or micrometer screws, those would be the gears you'd choose. Obviously you'd also need a perfect lead screw with no wear.

The reality is that some slight error is tolerable; in fact it's unavoidable. There are other gear combinations that offer a more convenient metric conversion, albeit with a tiny error.

Small Transposing Gears a GREAT ALTERNATIVE!

On the 9 and 10 K the 80 63 tooth transposing gear can be LEFT INSTALLED ALL THE TIME to enjoy a QUIET gear train!

No other transposing gear (47/37 or 127/100) allow this!

A common metric transposing pair is 80 and 63 teeth. Compared to the perfect ratio of 1.27, these gears will give you

1.26984

... That's an error of 0.0125%, which is only 0.0015" per foot. For any normal length thread you'd be hard pressed to measure the error, much less notice any functional difference. In return for this small compromise you get a pair of gears only a few inches in diameter. They'll fit within the factory gear cover and the cost will usually be lower.

The "other" metric transposing pair is 47 and 37 teeth. Compared to the perfect ratio of 1.27, these gears will give you 1.27027027... That's an error of 0.021%, which is nearly DOUBLE the error of the 80/63 tooth gear.