-40%

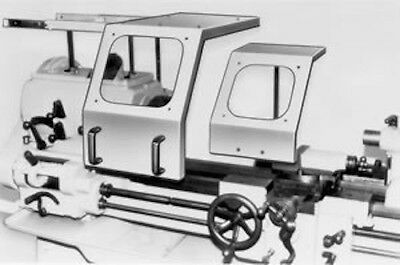

Flexbar Machine SLIDE-TRACK LATHEGUARD, 24" CHUCK CAPACITY,14" WIDE #13079

$ 789.35

- Description

- Size Guide

Description

SLIDE-TRACK LATHEGUARDHeavy-Duty 14 Gauge Steel Shields with LEXAN windows mount over headstock and slide over chuck for maximum protection! Allows easy access to the point of operation when power is off.

The "Minor" Slide-Track Latheguard features two (2) 3/16" thick LEXAN windows. Being situated on the top and front inclined panels, these windows provide excellent visibility for the operator. The front panel hinges up to allow access to the controls and settings of the machine - The "Minor" is designed to guard lathes having chucks ranging from 10" diameter up to 24" diameters.

The "Major" Slide-Track Latheguard provides maximum operator protection on standard machines or large CNC lathes with chucks ranging up to 48" diameter. These guards incorporate one LEXAN front panel window and do not require a top window.

SHIELDS SUPPLIED WITH OSHA ORANGE OR YELLOW BAKED ENAMEL PAINTED FINISH FOR LONG WEAR.

Model No. 13079

has a chuck capacity of 24".

All hardware is included with easy-to-follow instructions.

A heavy-duty guard can be installed on any size lathe. Simply screw the 4 pillar posts supplied at 4 sites around the headstock and then slip on the track assembly chassis. Now mount the shield. Pillar posts, in relation to crossmembers are adjustable vertically hence easily positioned around the headstock without interference.

Installation Instructions:

Remove all packing material from the shield and its mounting assembly

Measure how high the underside of the shield is to be above the headstock of the lathe in order to clear the chuck. Then cut the mounting pillars to length if necessary.

The four pillars can then be bolted to the headstock using M8 bolts, making sure that the assembly is located so as to allow the shield to slide back far enough to expose the chuck.

The pillar can be fixed anywhere along the length of the crossmembers, and either to the right or left of them by sliding or rotating the cast boss into which it locates the cast boss clamps to the crossmaker and pillar with grubscrews.

This flexibility of mounting position ensure that the pillar can be fixed without interfering with any part of the machinery housed within the headstock.

With the chassis located to the pillars, fix the shield (any model) to the chassis using six socket set screws provided, and check that access to the machine is not impeded.

Froo www.froo.com | Froo Cross Sell, Free Cross Sell, Cross promote, eBay Marketing, eBay listing Apps, eBay Apps, eBay Application